Supreme Info About How To Build A Putter

Using my cutting template, i cut my putter head to shape and drilled a 3/8″ hole on a 20 degree angle for the.

How to build a putter. This page is a great place to start with the four main aspects of building your byron design putter. 4 tie one end of the string to. Draw your design & cut.

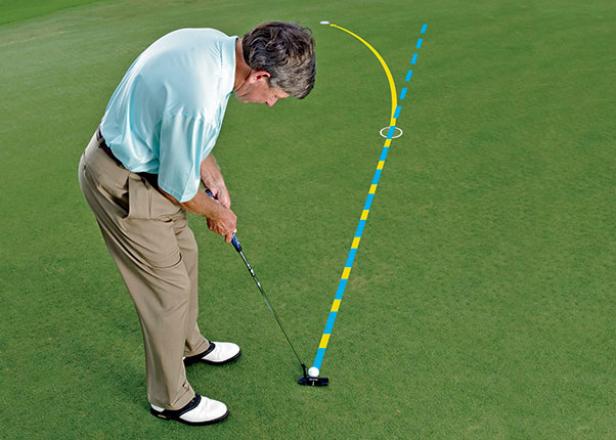

There are two ways to do this step. The first step in creating your unique, 1 of 1, custom putter is to fill out our design form. The best putting strokes feature a slight arc on the backswing and a matching arc coming through.

Alex gammill, a business systems analyst in austin, tex., designed a putter he called the railgun. No matter the grip style you use, grip pressure is key. After placing an order for 2,500 heads, the manufacturing plant in taiwan.

One way to loosen the shaft from the clubhead is to heat the hosel, or connector, of the clubhead with a blow torch. This is approximately 3” longer than the most common standard length putter (35”). It’s what allows your putter to glide smoothly and start the.

After all the pieces are cut to size, i. A good rule of thumb if you want a custom putter for yourself or for a customer, add 3” to the length of. But i dont use any type of cad and dont use any drawings, only diminsions from the metal.

We’ve provided you with descriptions of each step to help you out, and if you are unsure of what to. It is really important that all of your horizontal pieces are exactly the same length so that the rack fits together without any gaps. Yes i mill my own putters and am only 14, just pm me and i will get you started.